How Bo-Dyn Bobsled was Born

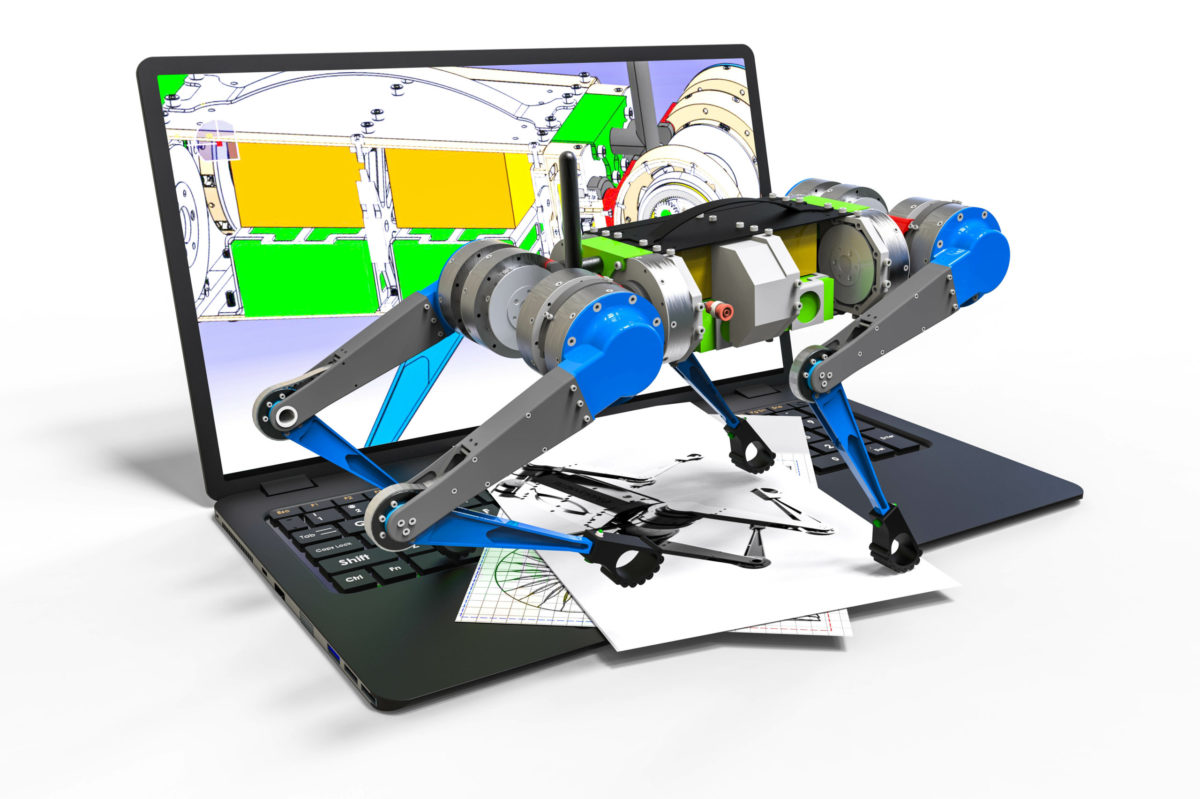

One of the universal challenges that designers can impact is weight distribution. SolidWorks allows the Bo-Dyn Bobsled Project to effortlessly implement 3D scanned images of sleds made using hand to determine where and how to incorporate new supports to make the design better. 3D viewing enables the team to test the weight and fit of components, and package them without the need to build prototypes.

Before partnering with SolidWorks, the Bo-Dyn Bobsled project had to develop prototypes using hands. There was no alternative, and this meant spending a lot of time and money on the models. 3D building and testing allow incredible precision that translates seamlessly to the final product. It is this degree of freedom that enables the Bo-Dyn Bobsled Project to better its medal-winning design.

Unlike many international bobsled teams that receive million-dollar design and research funding from the government, the Bo-Dyn Bobsled Project has to innovate on a budget. The company has to make the most out of what they have which is significantly lower than that of their competitors. The cost and time savings associated with getting designs right the first time and meeting tight deadlines wouldn’t have been a reality without the assistance of SolidWorks. Teaming up with ModernTech allowed Boy-Dyn to quickly learn the key features of SolidWorks. However, Bo-Dyn has barely scratched the surface of SolidWorks’ geometric and simulation capabilities. They are striving towards being more competitive and staying true to their commitment to developing the world’s fastest sled.

There have been significant technological advancements within bobsled construction in the United States since the Bo-Dyn Bobsled Project was launched in 1992. In terms of design, SolidWorks’ division Dassault Systems has developed 3D digital mock-ups to improve the weight distribution of bobsleds. deBotech produced advanced composite parts and lighter carbon fiber used in the bodywork of bobsleds while Exa Corp has optimized airflow over the sled’s body using computer-generated simulation.

The Bo-Dyn Bobsled Project has stayed true to its vision of designing, producing, and supplying US-built racing sleds. Before the Bo-Dyn Bobsled Project joined the bobsled scene, most Americans knew more about Jamaican bobsledders than they did about American bobsledders. However, this has changed significantly. Not only are Americans more knowledgeable about their own bobsledders, but they have gone on to make history by earning their first gold medal since 1948 in the men’s category. Winning in the Olympics is a great accomplishment since you are competing with the world’s best and brightest. The sky’s the limit for the Bo-Dyn Bobsled Project. As the company strives to be more innovative and competitive, we can only expect Bo-Dyn to continue to set bobsled standards for the United States, and for the World.…

Learn more →